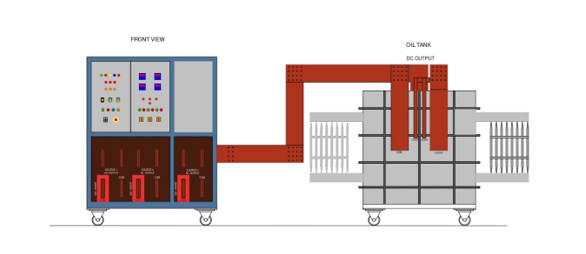

The SCR Make 10kA AC High Current Injector with DC option is custom-built system is designed to support high-current testing such as for Temperature Rise Test or other evaluations as per your required standards (IEC, UL, ASTM, etc.). Supported by NI LabVIEW and PC-based Testware software, it is controlled via a common industrial PC interface, enabling precise, automated, and safe testing of high-current electrical components such as Air Circuit Breakers (ACBs), Busbars, Connectors, Switchgears like MCCBs, MCBs, Contactors, and Protection Systems.

The setup includes:

Designed for testing applications requiring low-voltage, high-current delivery, the bench performs electrical validation tests. Its modular and scalable structure ensures operational reliability and system safety. It supports precise testing and programming for trip/non-trip and overload verification of ACBs and similar devices.

Configuration: Custom Built High Current Source System (AC/DC-3Phase)

| Source | Cooling Type | Variac Type | Current Rating | Input Type | Output Type |

|---|---|---|---|---|---|

| Source 1 | Inbuilt Air Cooling | Air-Cooled Variac | 10A–1000A | 415V AC 32A for each of 3 Phase | AC/DC(AC -1Phase & 3Phase) |

| Source 2 | Inbuilt Air Cooling | Air-Cooled Variac | 30A–2500A | 415V AC 100A for each of 3 Phase | AC/DC(AC -1Phase & 3Phase) |

| Source 3 | External Oil Cooling | Oil-Cooled Variac | 500A–10000A | 415V AC 300A for each of 3 Phase | AC/DC(AC -1Phase & 3Phase) |

Flexible usage allows combinations such as AC on Source 1 & 2 and DC on Source 3, or all three AC sources simultaneously with different current settings.

Indication

| Component | Accuracy Class | Max Range | Features |

|---|---|---|---|

| Digital Voltmeter | Class 1 | 0–500V AC | For all 3 sources |

| CT – Source 1 | Class 0.5 | 1000A | Taps will be provided to measure & control the current accurately. The selection of CT range will be with contactors |

| CT – Source 2 | Class 0.5 | 3000A | Taps will be provided to measure & control the current accurately. The selection of CT range will be with contactors |

| CT – Source 3 | Class 0.5 | 10000A | Taps will be provided to measure & control the current accurately. The selection of CT range will be with contactors |

| Shunt (Each Source) | — | 0.1Ω / 50W | For oscilloscope-based current waveform view for each source |

Note: (Oscilloscope is supplied as an additional option – not in default)

Safety & Protection Features

| Feature | Description |

|---|---|

| Electronic Protection | Over Current Trip fixed at +5% for 5 sec for current exceeding (1000A / 2500A / 10000A) |

| Incoming Protection MCB / MCCB | Schneider Make: 12A/4P (Source1), 4P (Source 2), MCCB 250A/4P (Source 3) |

| Earth Fau lt Relay | For switching off the system if earth leakage current exceeds 30 mA |

| Auxiliary MCB Protection | For control and peripheral systems |

| Fault Indication | Lamps, hooters for system fault alert |

| Smoke & Fire Detection | Sensors with system shutdown trigger |

| Output Tap Safety Interlock | Prevents wrong tap engagement |

| Maintenance Safety | Sticker labeling, proper earthing, safe component layout |

| Emergency Controls | Push buttons for Test ON/OFF, Reset, Emergency STOP |

| Backup Contactor Cut-off | Heavy-duty Schneider contactors per feeder |

Custom Built High Current Source System (AC/DC – 3 phase) for Schnieder Electrical Pvt. Ltd., Bangalore (July 2025)